Tegheim - Home made 4 Rotor Wolvo project

#876

for a track car, smaller diameter is better, just like less weight is better (for the same reason) but it does make it more difficult to launch/start from a stop...

I'm not sure I would want to drive a 4.5" clutch with a 4.5 lb flywheel on the street

#880

Senior Member

Thread Starter

I have been thinking about the intake. I would want to have tapered runners, but because "someone" decided to lower the entire body over the frame, there isn't much space above the engine.

This means that I have to make a turn on 156.5grd pretty tight around the engine and land on the block. The options are to cast runners in plastic, carbon fiber or aluminum perhaps?

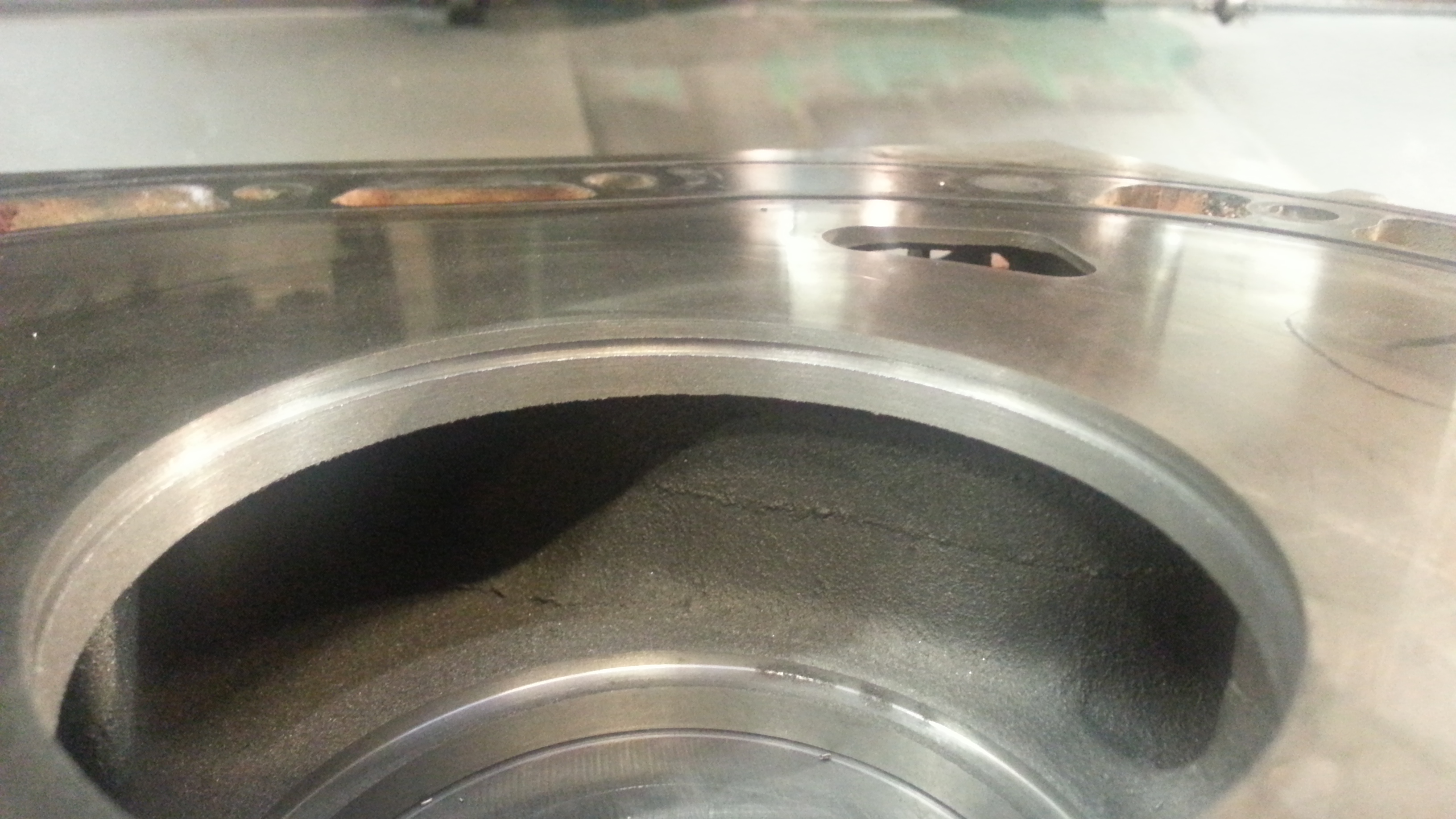

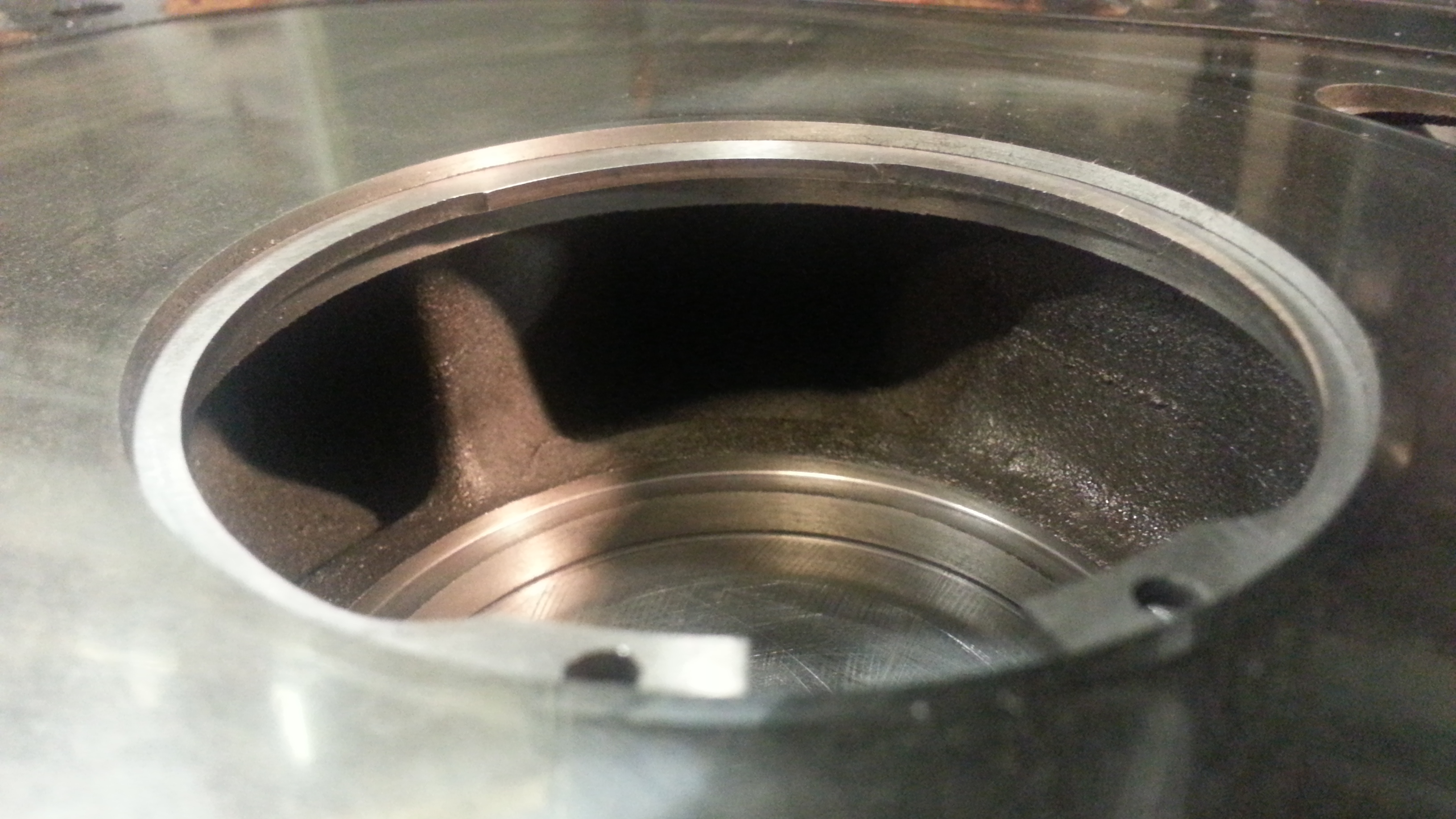

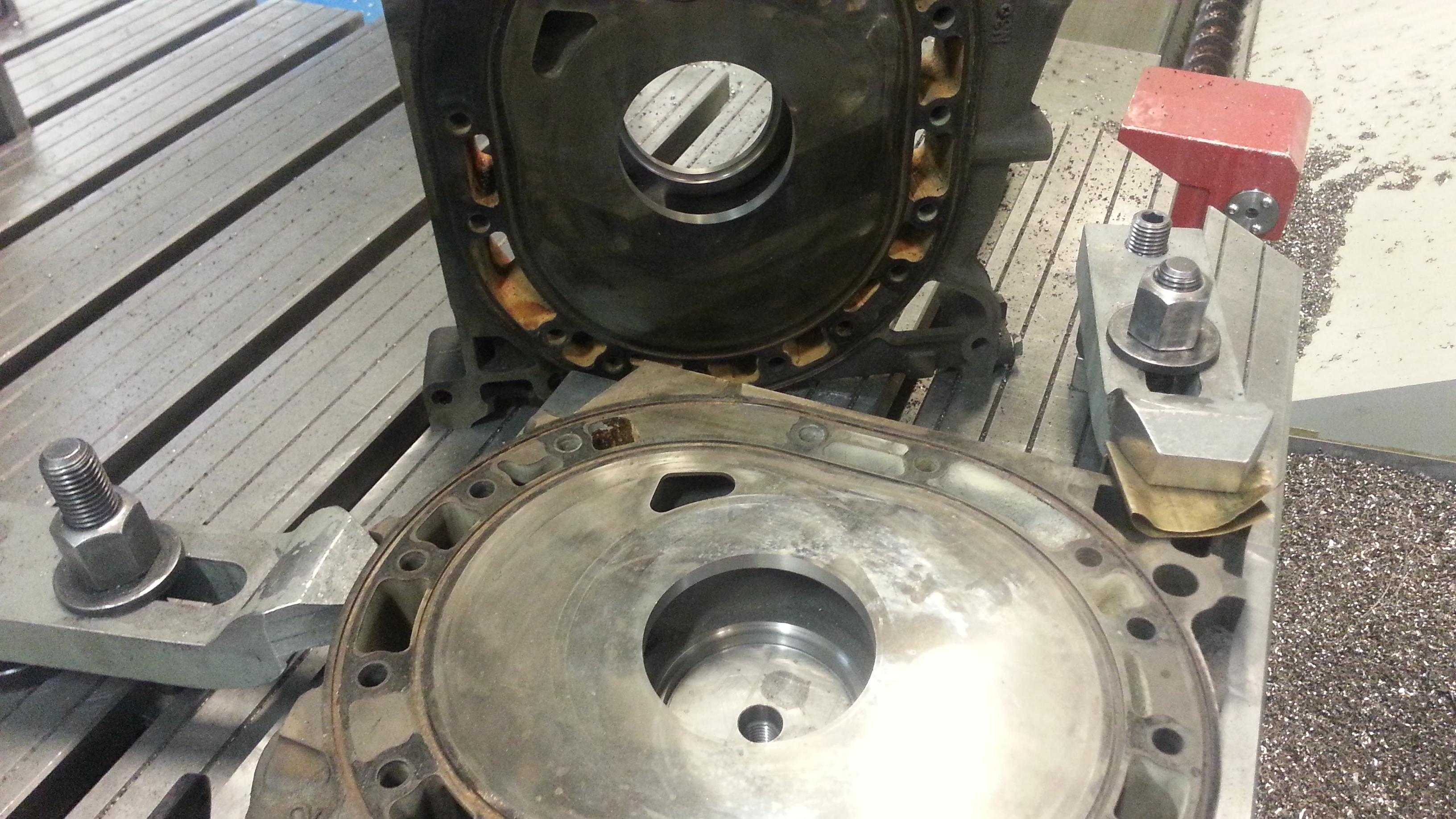

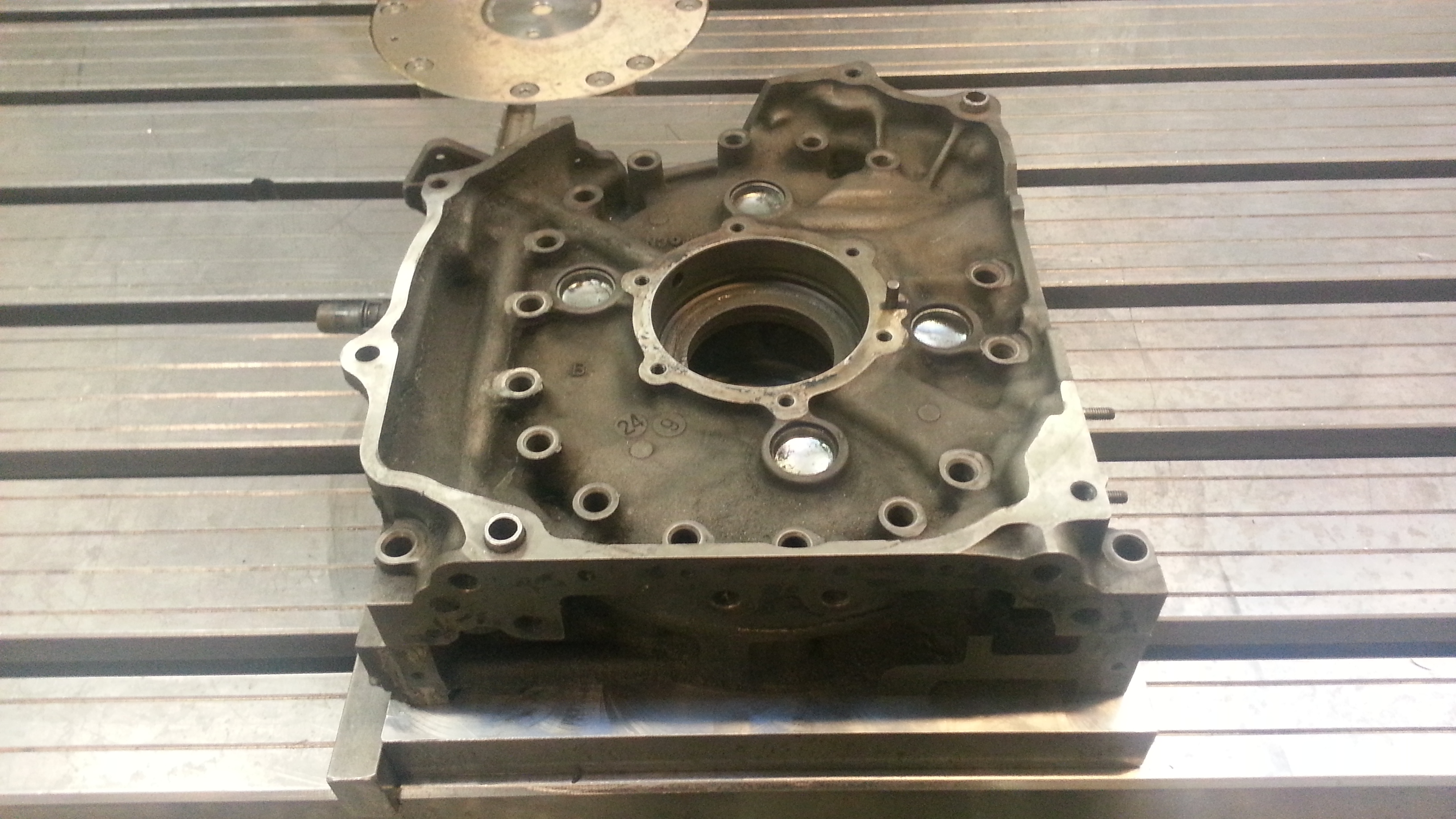

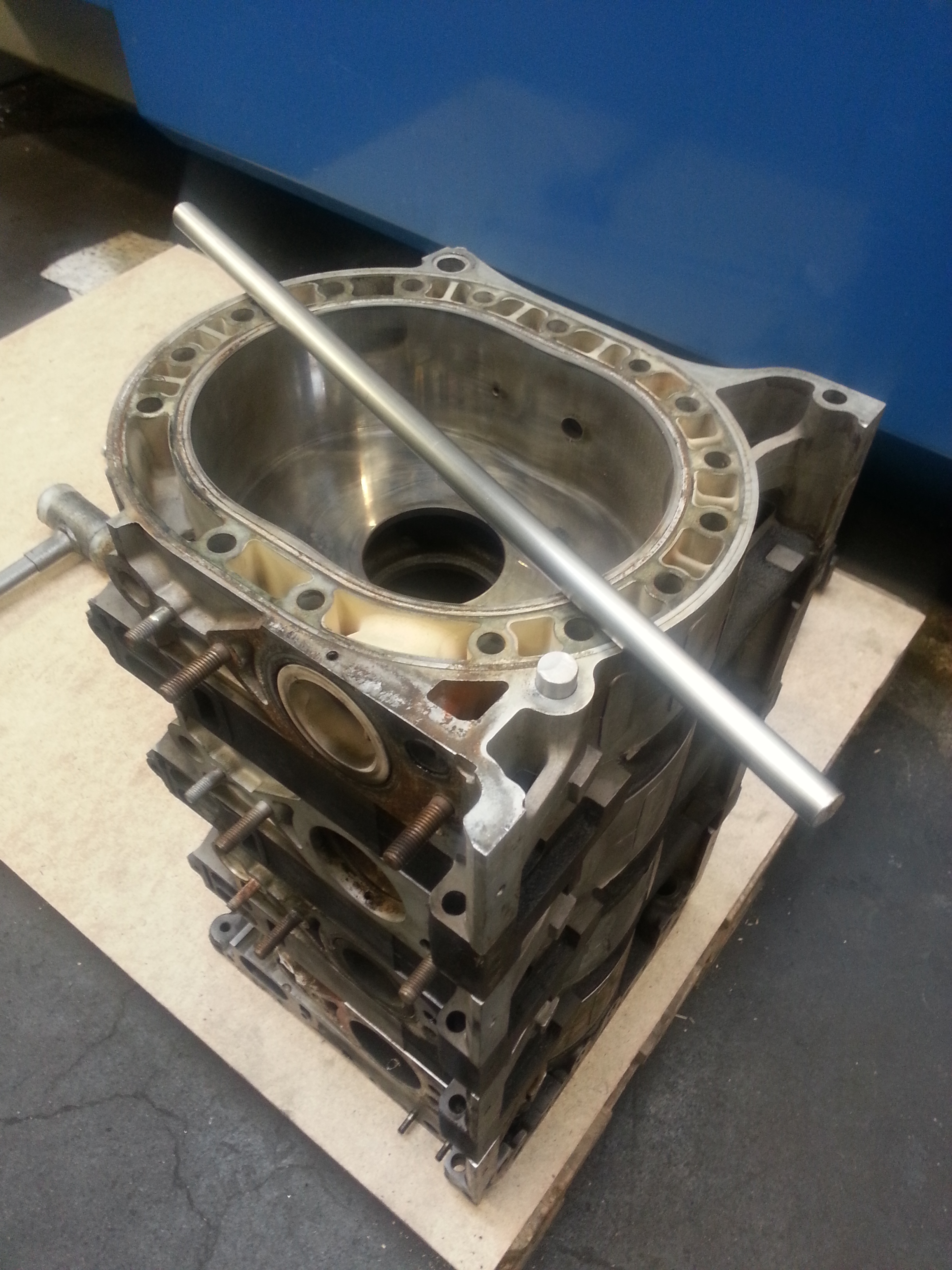

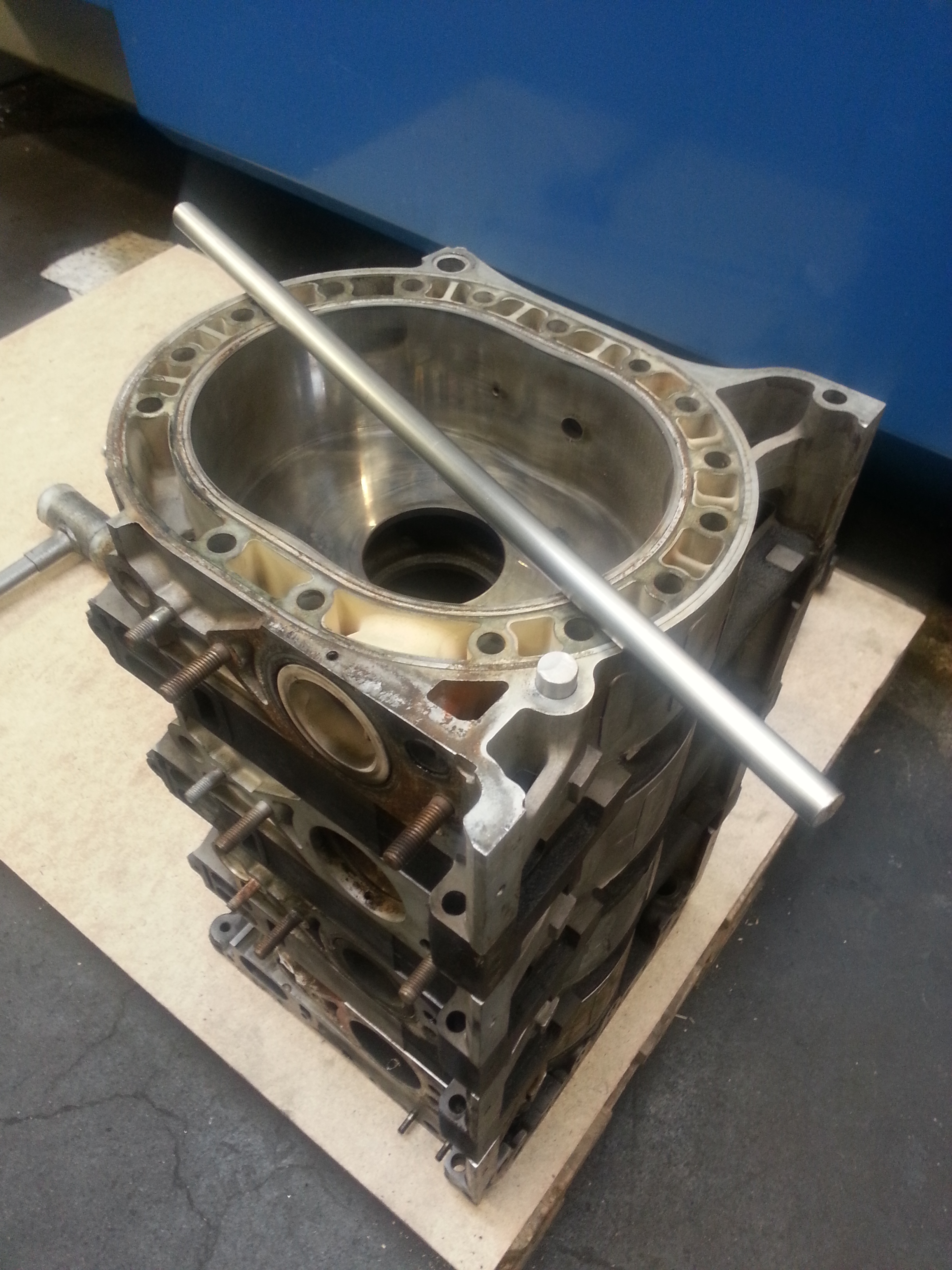

Today I continued to mod my intermediate irons for more bearings.

First I layed a the intermediate and clamped it. Then either front or rear iron onto to indicate the centrum.

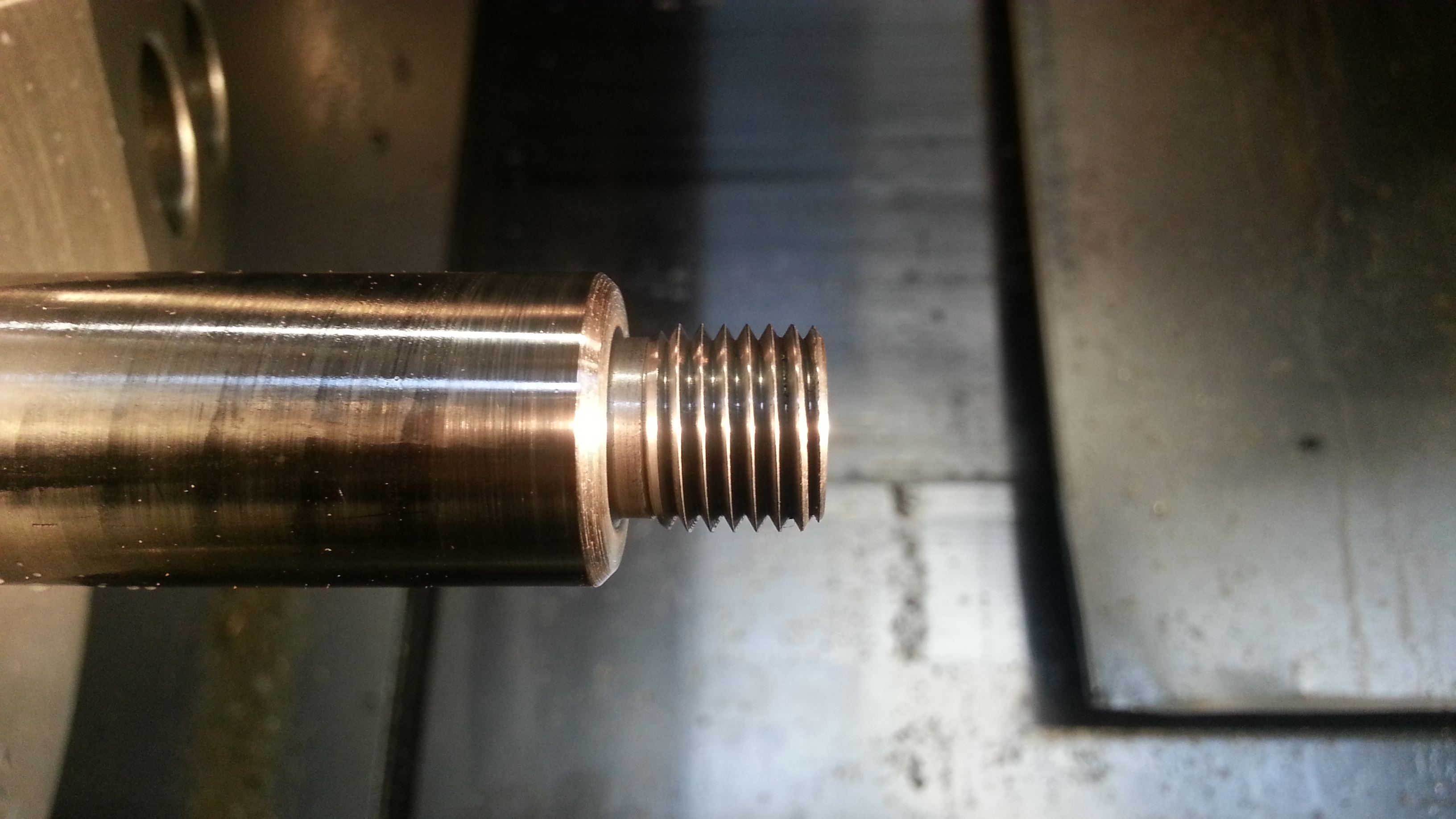

Machined two new very tight dowels. As tight as possible.

Even then you can move the plate 0.015mm in both directions. I alinged in the middle of the play.

This means that I have to make a turn on 156.5grd pretty tight around the engine and land on the block. The options are to cast runners in plastic, carbon fiber or aluminum perhaps?

Today I continued to mod my intermediate irons for more bearings.

First I layed a the intermediate and clamped it. Then either front or rear iron onto to indicate the centrum.

Machined two new very tight dowels. As tight as possible.

Even then you can move the plate 0.015mm in both directions. I alinged in the middle of the play.

#882

Senior Member

Thread Starter

#885

Exhaust Manifold Leak

Saw that, but I was wondering how one would do it when having a cast rotor. EDM would be the best, but really slow and expensive, hard to believe they edm it in the factory, so they must have a .7mm end mil then?

#886

Senior Member

Thread Starter

A 0.7mm Endmill is very slow also.

You need extreme spindelspeed, approx 20000rpm maybe?

Also a very long mil, and slow feed.

Did calculate this on mine, but with my slow machines it would take a year :-)

You need extreme spindelspeed, approx 20000rpm maybe?

Also a very long mil, and slow feed.

Did calculate this on mine, but with my slow machines it would take a year :-)

#887

Exhaust Manifold Leak

damn, then they must have some special fixture/lathe where they spin the rotor in the correct radius and lift tool when it is in the corner seal hole? maybe edm is then the only feasible solution for a small batch of exotic material rotors :/

or one must make compromises and do it this way

https://www.rx7club.com/attachments/...2122010414-jpg

or one must make compromises and do it this way

https://www.rx7club.com/attachments/...2122010414-jpg

#889

Exhaust Manifold Leak

who knows =) just looking out to what tooling would be mandatory. only hard part seems to be these grooves, all the rest can be done with conventional equipment

#891

Senior Member

Thread Starter

#894

Senior Member

Thread Starter

First of all I'm very proud to annouce this link

http://www.build-threads.com/general...uilds-of-2013/

Back on topic.

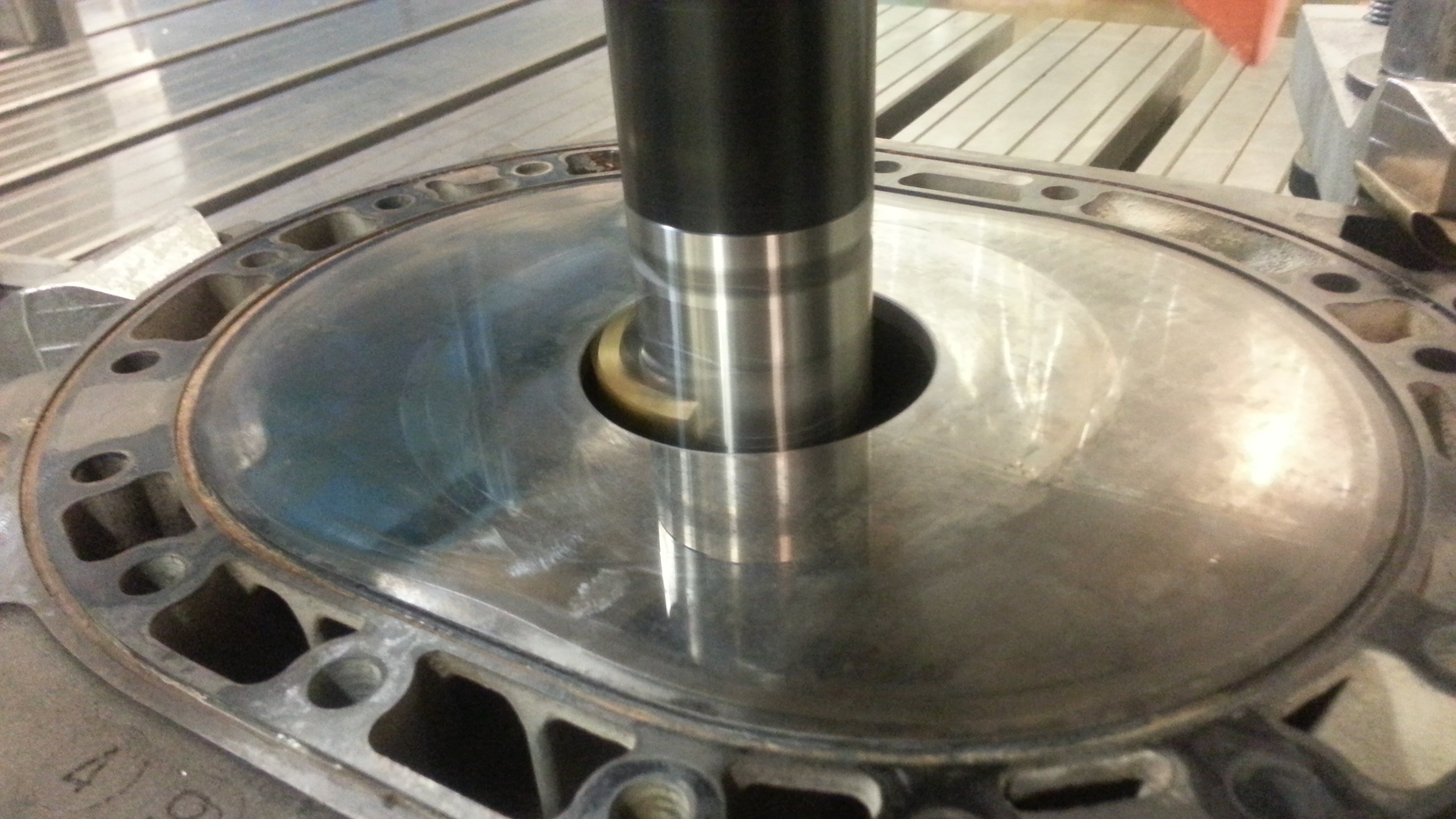

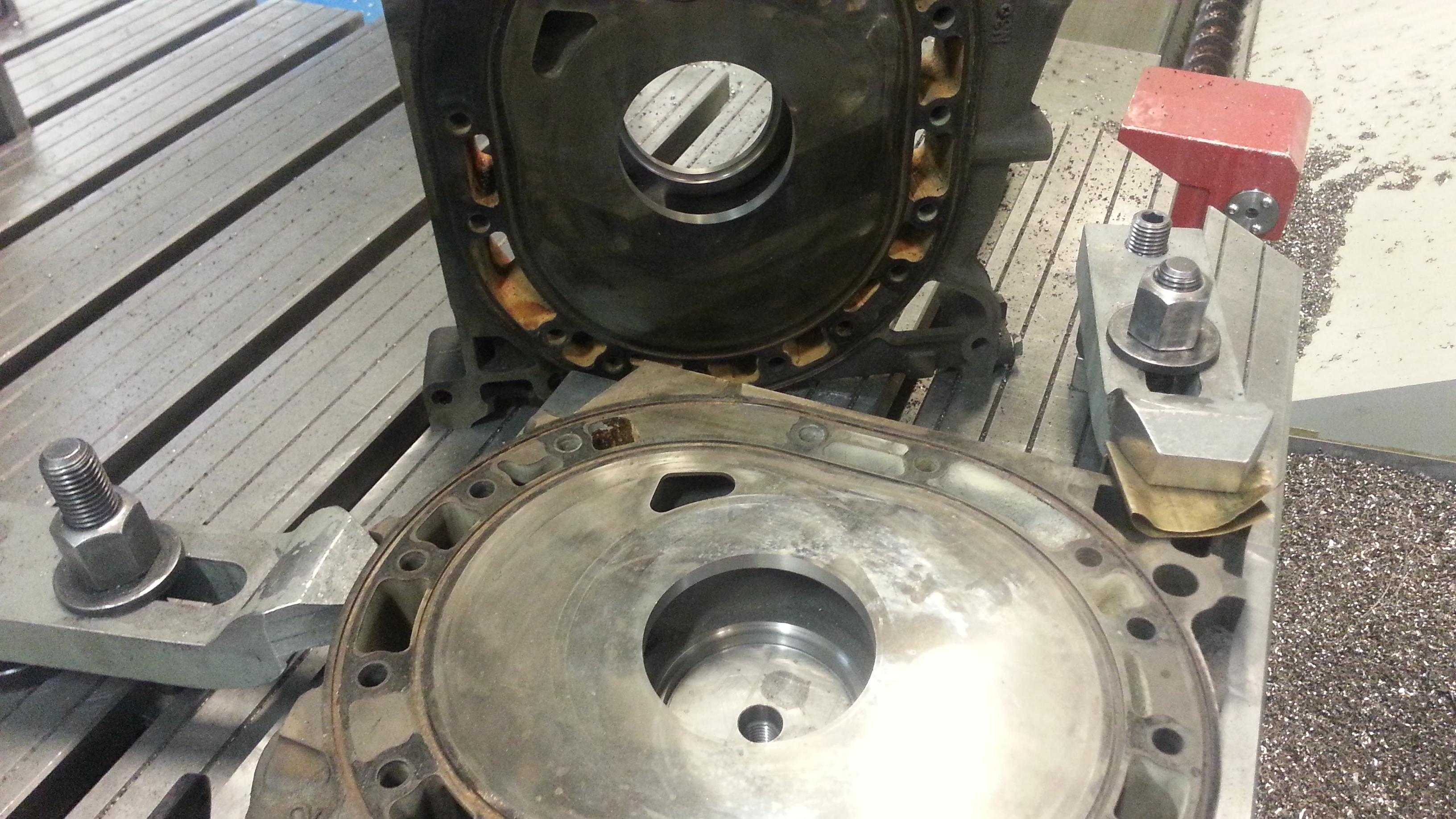

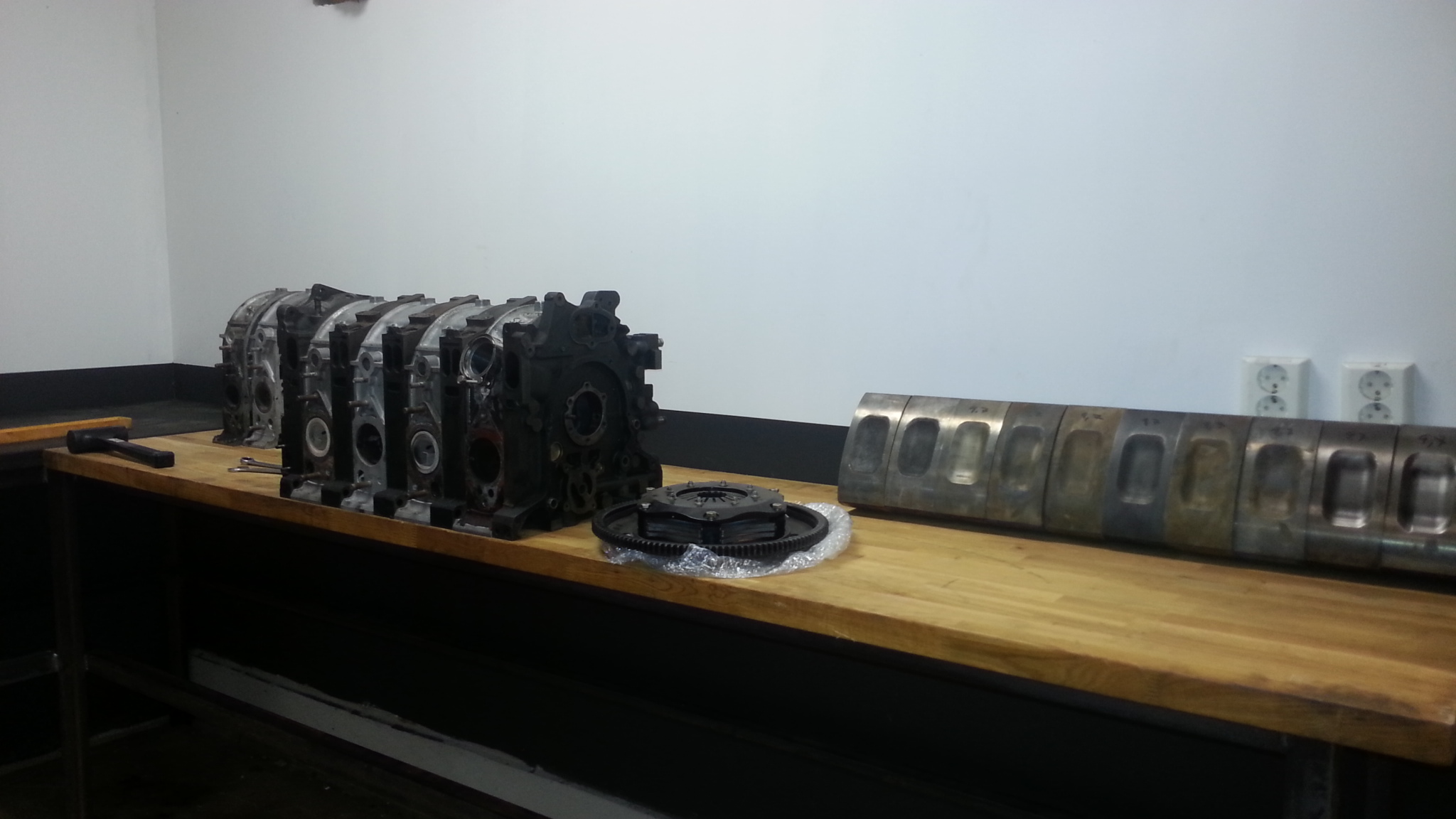

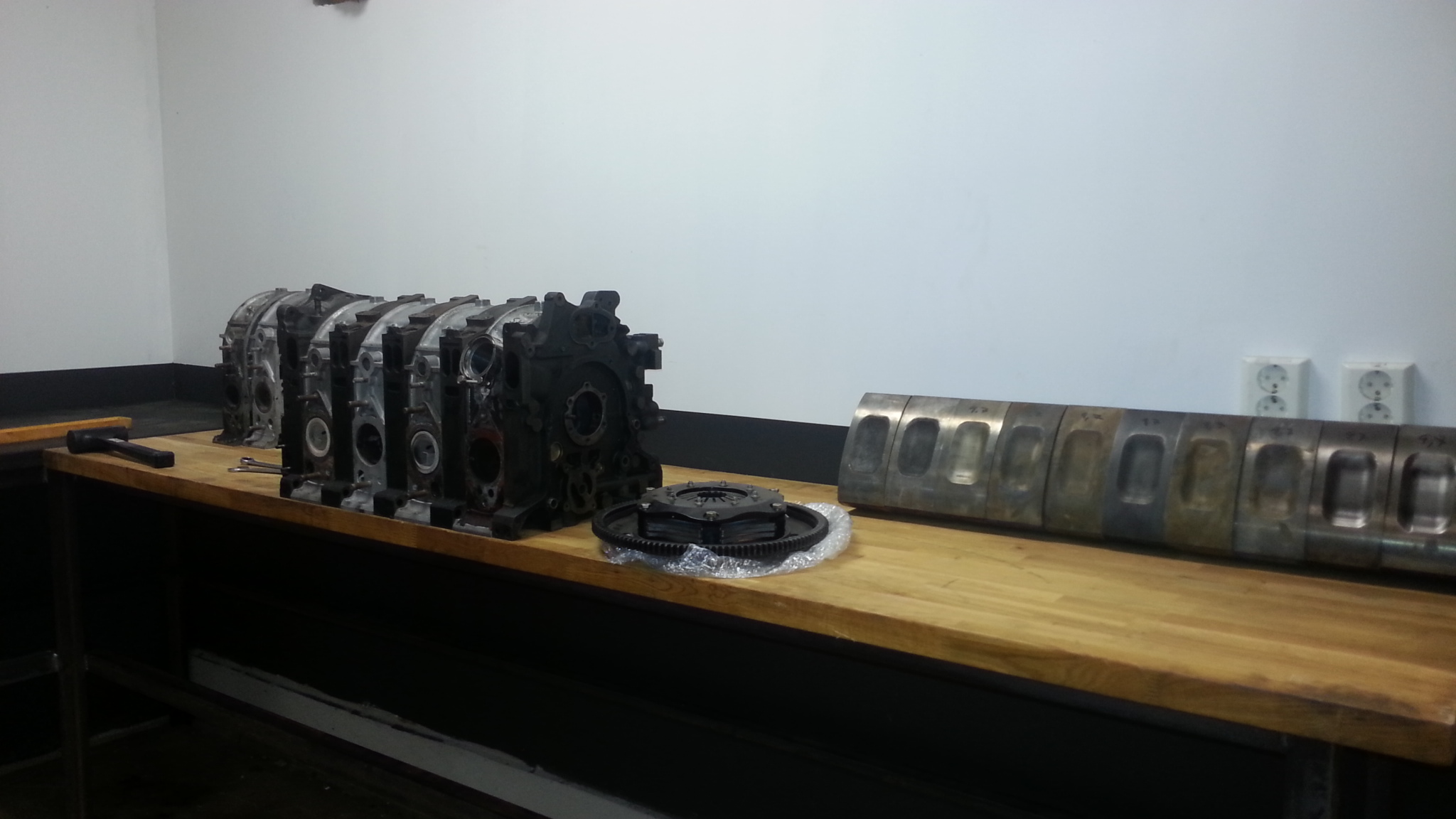

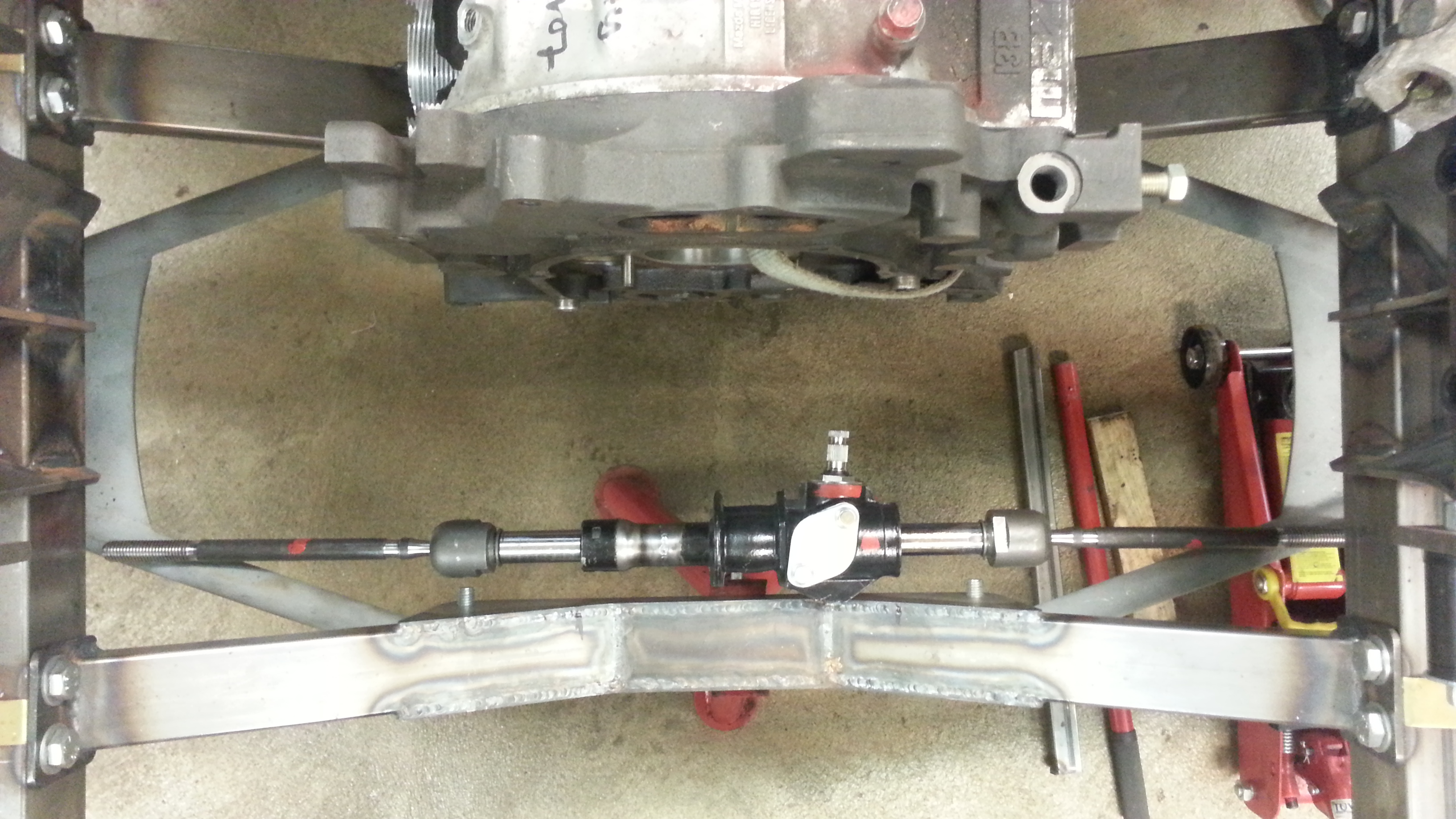

Builded some new benches to work on, and then started to assembly the dummy again to put back in the car for some measurements.

Tonight I was out on the highway and meet a friendly truckdriver from Czech Republic. He had brought a 20B flexplate from hIGGI on the forum. Thanks alot for that hIGGi!

Also got some V-band-clamps today. Perfect size. Small and tight, just like we want them.

http://www.build-threads.com/general...uilds-of-2013/

Back on topic.

Builded some new benches to work on, and then started to assembly the dummy again to put back in the car for some measurements.

Tonight I was out on the highway and meet a friendly truckdriver from Czech Republic. He had brought a 20B flexplate from hIGGI on the forum. Thanks alot for that hIGGi!

Also got some V-band-clamps today. Perfect size. Small and tight, just like we want them.

#896

Senior Member

Thread Starter

Not much is happening at the moment.

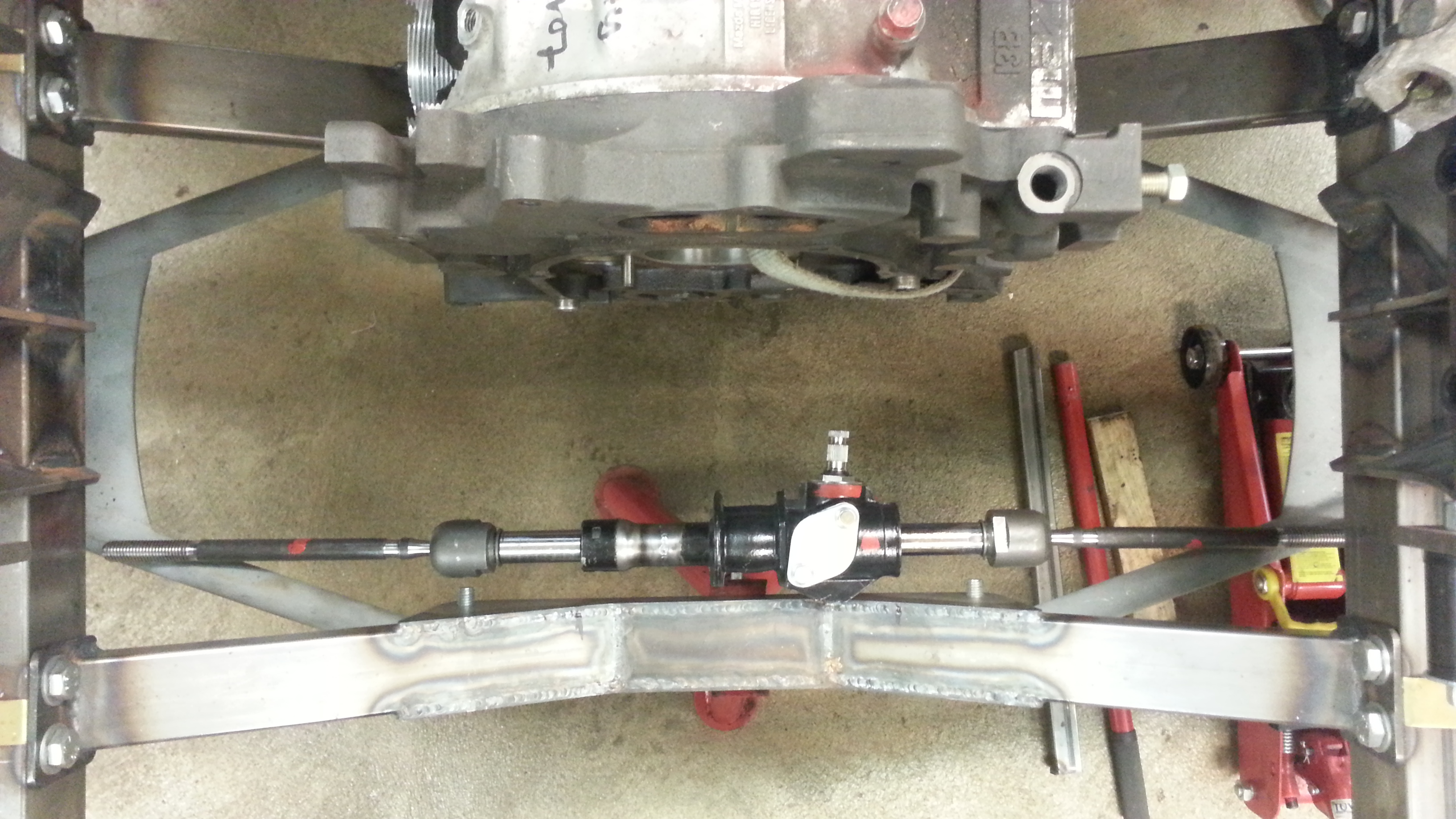

I shortened my steering rack at last. Cut 220mm of an let 200mm be left.

Took some M24-nuts and machined out the threads. Then put them over my 4-link rods for adjustments later on. Just a little work with the TIG, and they are ready for some paint.

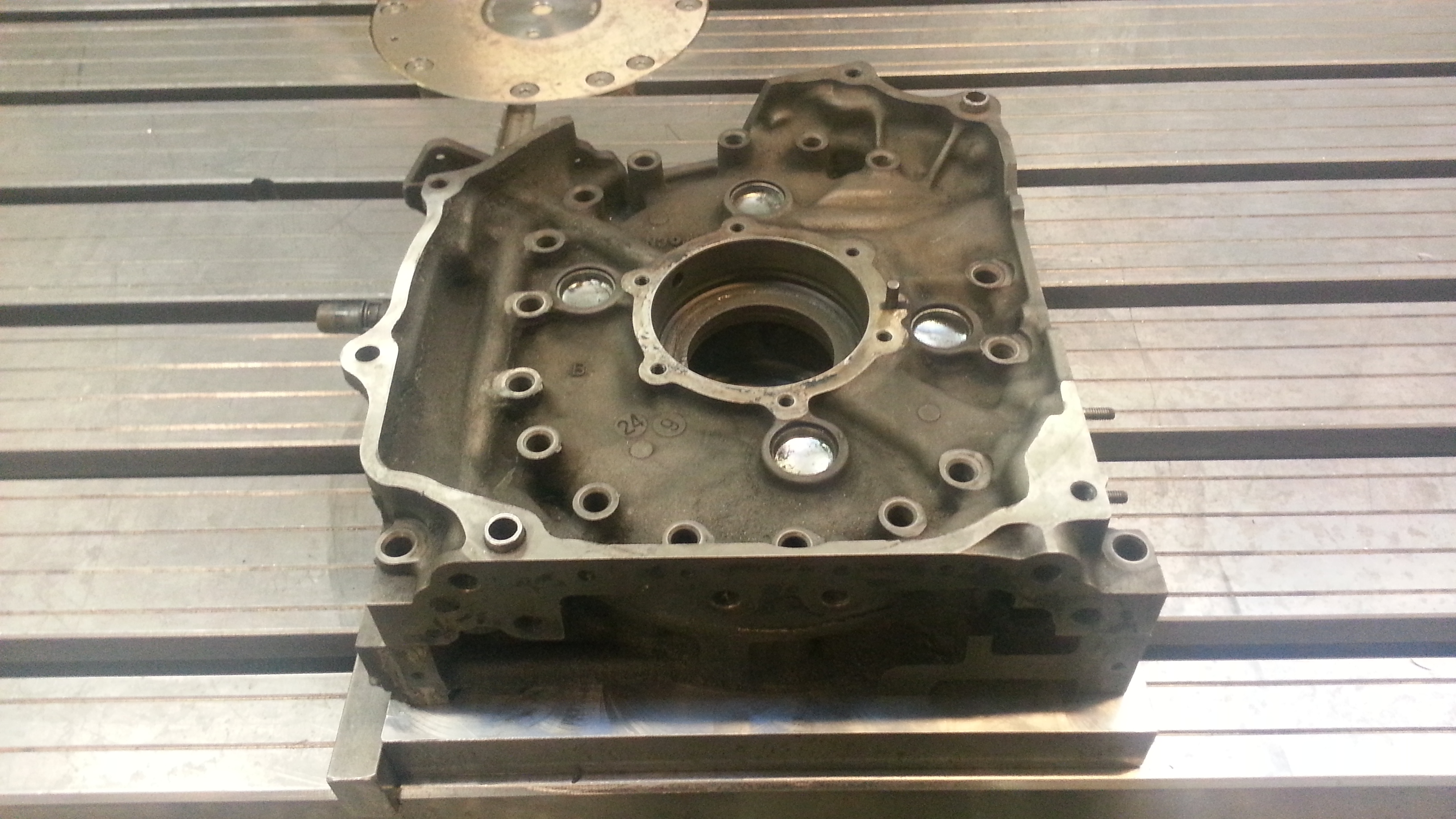

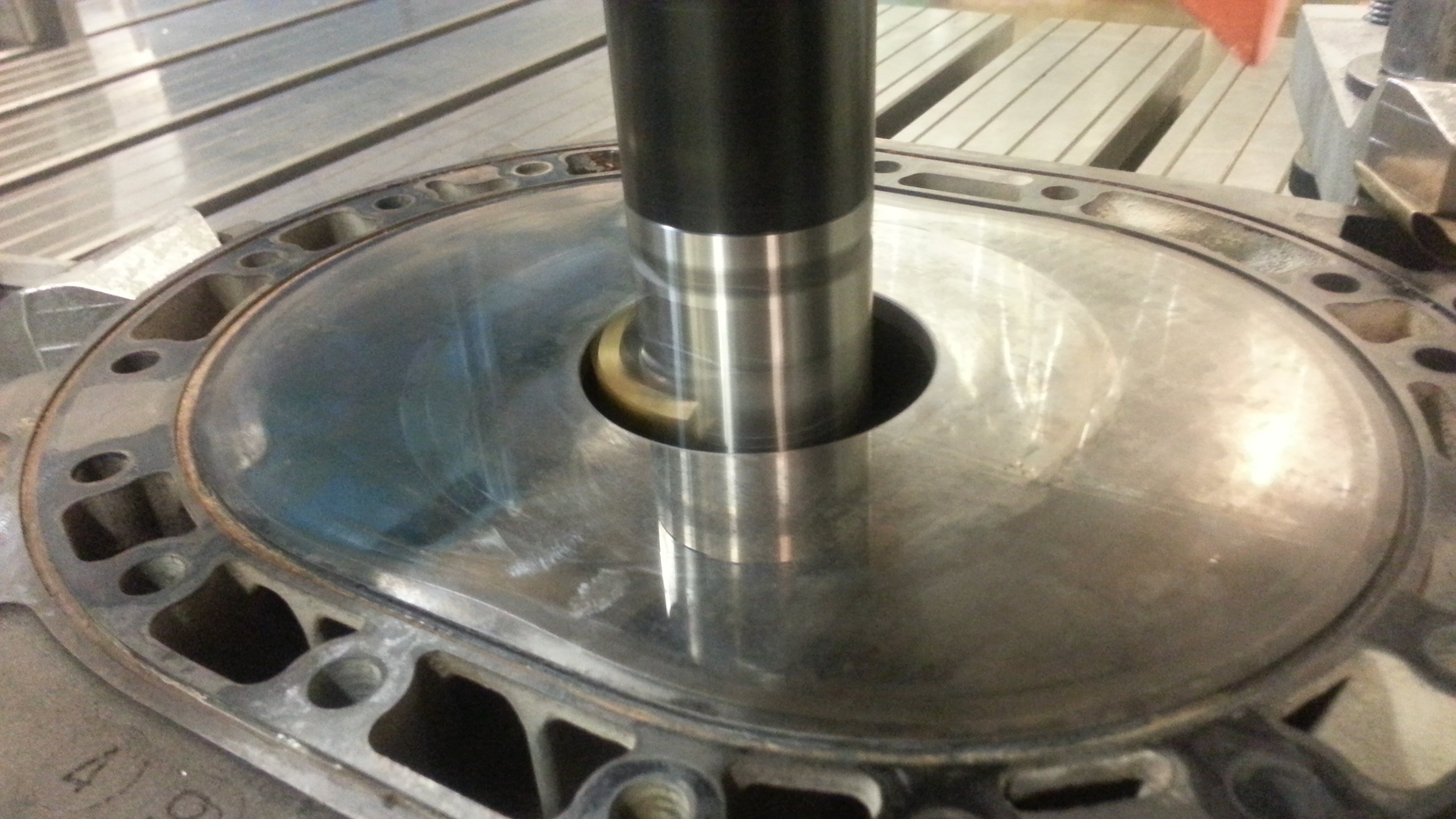

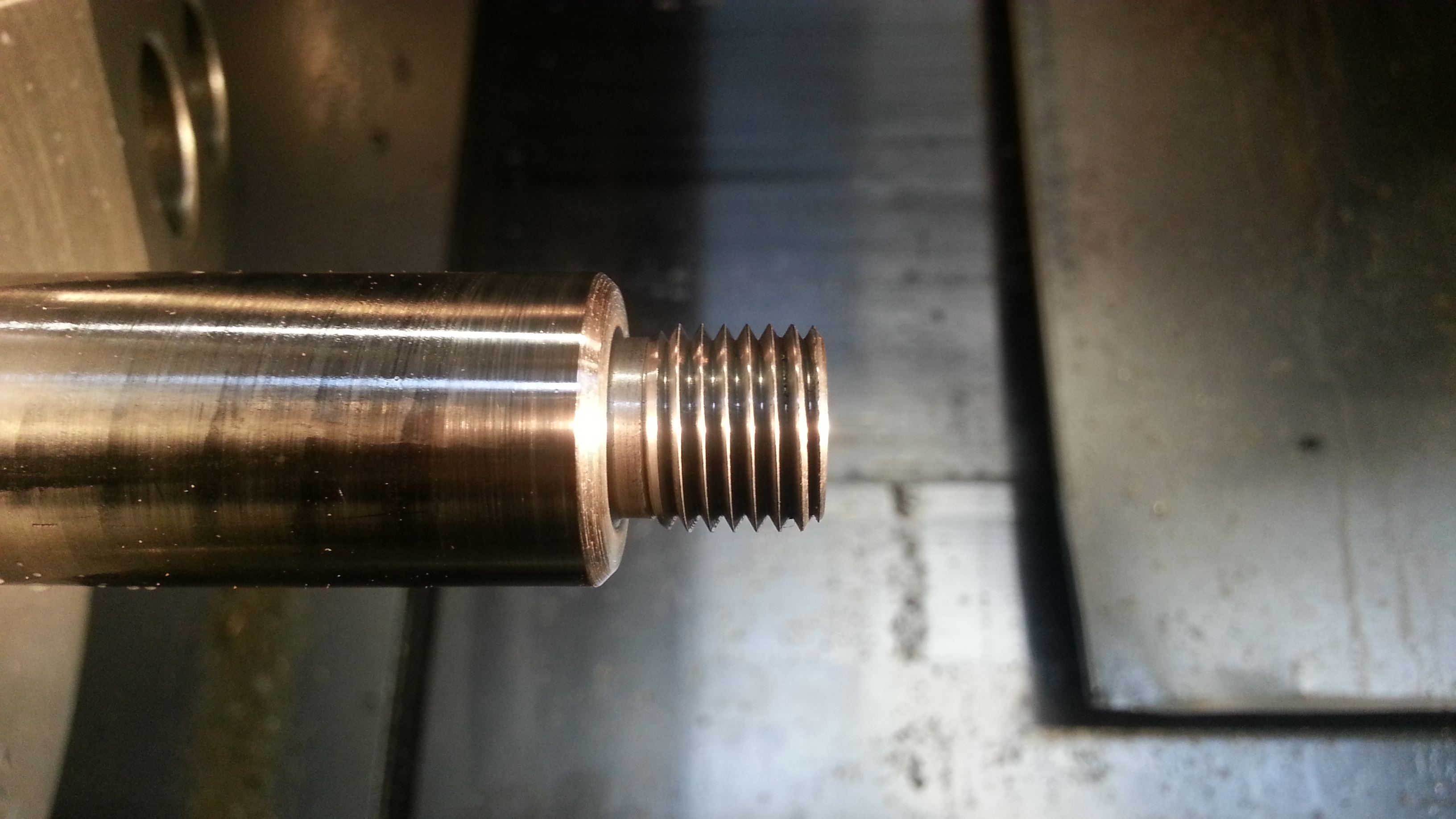

Are going with these 15.99mm solid dowels straight through the engine. Better off than the OEM.

I shortened my steering rack at last. Cut 220mm of an let 200mm be left.

Took some M24-nuts and machined out the threads. Then put them over my 4-link rods for adjustments later on. Just a little work with the TIG, and they are ready for some paint.

Are going with these 15.99mm solid dowels straight through the engine. Better off than the OEM.

#900

Exhaust Manifold Leak

drill out the brass plug in the front housing and feed the front bearing from there.

the bearings in this custom intermediate housings on this built will anyway have to be fed from an external line trough a steel or brass pipe.

the bearings in this custom intermediate housings on this built will anyway have to be fed from an external line trough a steel or brass pipe.